|

|

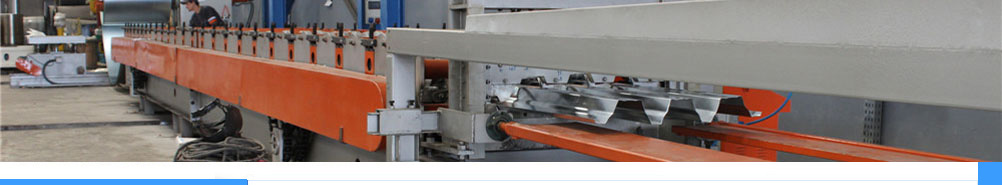

| Home -> Main Equipment And Specifications -> Door frame roll forming machine |

|

|

Main technical parameters

1. Matching material: galvanized steel coil, thickness less than1.5mm

2. Material thickness range: accord to drawings

3. Main motor power: 7.5kw

4. Forming speed: 4-8m/min(include cutting time)

5. Hydraulic power: 3.5kw

6. Quantity of stands: about 16

7. Shaft Material and diameter: ¦µ70mm, material is 40Cr

8. Material Of The Stations: A3 steel

9. Tolerance: 3m+-1.5mm

10. Way Of Drive: 1.5 inch single chain

11. Controlling system: PLC

12. Total weight: about 4.5 Tons

13. Voltage: 380V/ 3phase/ 50 Hz

14. Size of the machine: L*W*H 5.5m*1.2m*1.2m

15. Material of forming rollers: Gcr 15

16. Material of cutter blade: Cr 12 mould steel with quenched treatment 58-62¡æ

Main composition of the machine

The machinery line consists of de-coiler with its base, material feeding and flatting , hydraulic servo punching, PLC cut to length system ,roll forming machine, run out table, control cabinet with PLC.

Working Flow

Decoiling the sheet -Coil strip feeding ¨CMaterial flatting- Hydraulic servo punching --- Cut to length system ----Roll forming---Plc control -Panels to the collecting platform¡ª Finish

Cutting and the control cabinet

Cutting

(1) Cutting motion: The main machine automatically stops and then cutting. After the cutting, the main machine will automatically start.

(2) Material of blade: CR12with heat treatment

(3) Length measuring: Automatic length measuring

(4) Tolerance of length: +/- 1.5mm

Control Box: Brand Panasonic

(1) Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase (this is can depend on customer request)

(2) Automatic length measurement

(3) Automatic quantity measurement

(4) Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved

(5) Length inaccuracy can be amended easily

(6) Control panel: Button-type switch and touch screen

(7) Unit of length: millimeter (switched on the control panel)

Packing List details

De-coiler x1set

Main roll forming machinex1 set

Control box x1 set

Hydraulic cutting x1 set

Hydraulic punching x1set

Simple Run-out table x1 set

Mold x1 set

|

|

| |

|

|